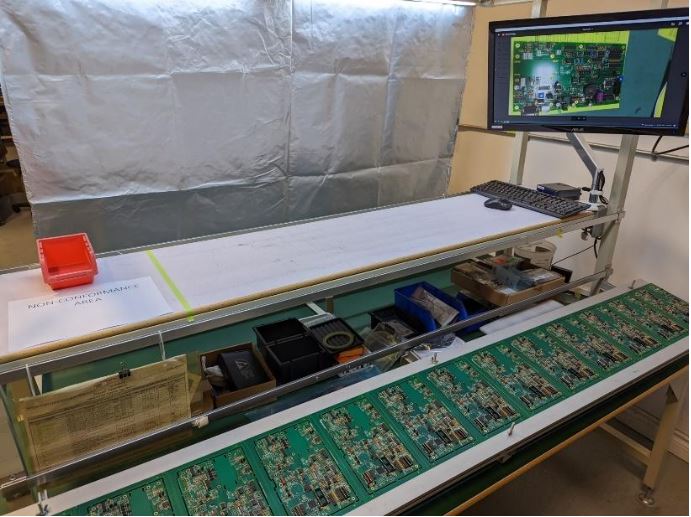

Through-hole Assembly

Through-hole assembly is a method for producing electronic circuits in which the components are installed through leads. It refers to the mounting process that inserts the leads to the drilled holes and solders the components on the boards by wave soldering, selective soldering, or manual soldering.

If the components require special preparation, they shall be prepared to the necessary dimension and shape while following the IPC standard. At U Choice, components placement is installed manually on the PCB, depending on the design, we provide the following services for soldering: selective soldering, hand soldering, and wave soldering.

Machine: Juki Cube 460 Selective Soldering System

Feature

- Automatic Solder Wire Feeder replenishing system

- Solder wave monitoring system

- Live process viewing camera

- High-performance Bottom-side Preheater

- 2 universal PCB carriers for up to 460mm by 460mm

- Quick exchange mini-wave soldering nozzle

- Solder at 0 degrees and 7 degrees

- Solder pot trolley system for quick change between alloys

Machine: Lead-Free Wave Soldering Equipment (GSD-WD300C)

- Efficient, energy-saving, lead-free, environment-friendly, safe, and brand-new design, simple operation, convenient maintenance

- Full computer control with windows XP interface, kinetic energy monitoring, greatly improving the work efficiency and reducing the production cost

- Automatic power system, frequency converter control, automatic board input system

- Flux spray system using a scanning spray nozzle, Japanese nozzles and rodless pneumatic cylinders and PLC control, accurate and reliable

- Preheating system uses 3-stage powerful air system, excellent heat preservation, temperature warm-up, temperature uniformity, no more than ± 2 degree

- Special alloy transportation chain claws, non-stick tin, reinforced, and ensure the quality of welding

- Tin stove adopts imported high-frequency conversion motor independent control, stable performance

- Lead-free solder furnace with independent design, environment protection, and safety, easy to clean

- Tin heating furnace uses high-speed PID and 2-step independent outer heating control, warm-up quickly and eliminates the flaws of stove tin explodes

- With time controller, can preset switch functions, tin stove machine heating picks up in 90minutes

- With black box memory function, can always get at production management records, improve work efficiency

- Reasonable design of environment protection, and automatic washing claw, ensure the cleanliness of claws

- The design is reasonable and safe with a sensitive fault alarm system, to ensure the stable performance and the safety of operators

Machine: Hakko FX-951 Soldering Station

- Temperature Range – 200° – 450°C (400° – 840°F)

- Ceramic Heated Tips for Quick Heat Conduction

- Low Thermal Recovery Time

- Set Temperature Lockout Key

- 30 Minute Automated Shutoff

- Low-Temperature Alarm