Advanced Equipment and Facilities

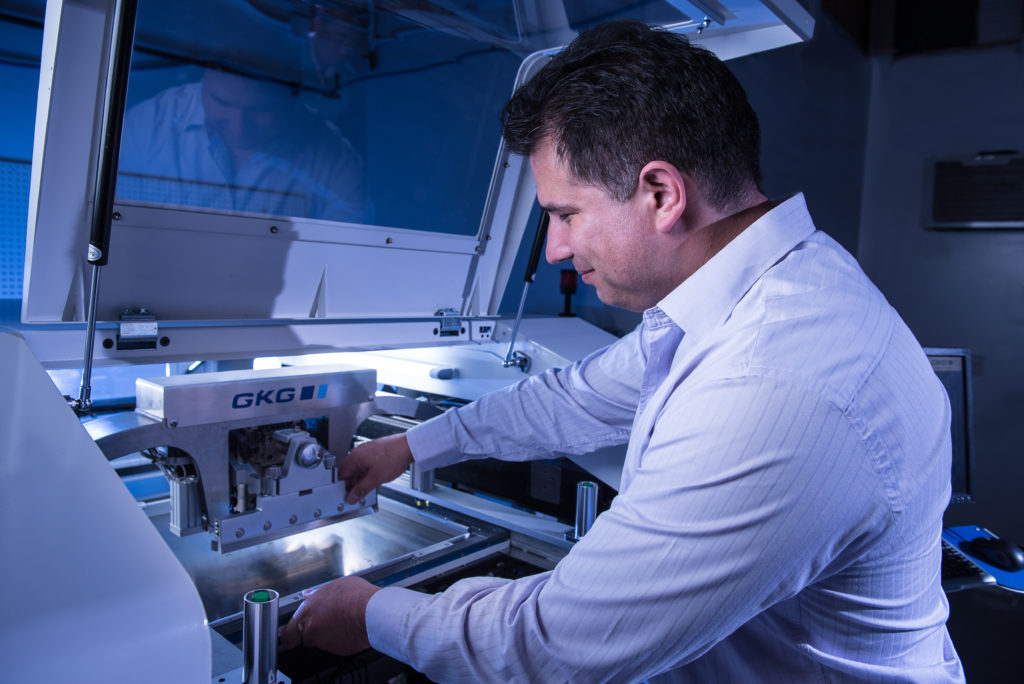

Fully Automated Screen Printer

High accuracy automatic printer provides 01005 printing. High precision StenTech laser stencils are used for best print and release control.

Pick & Place Machines (SM482/MC391)

Flexible component placement solutions for projects ranging from prototyping to high speed, high volume production runs. Accurate to 01005 component size for today’s most challenging surface mount technology (SMT) applications.

Convection Reflow Oven

The right equipment for both lead and lead-free production. Fully computer controlled with monitored, precise heating cycles.

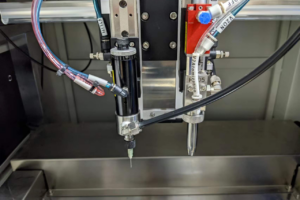

Automatic Selective Soldering System

High Precision automated thru-hole soldering for consistent high quality mixed technology assembly.

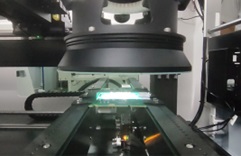

Automatic Optical Inspection (AOI)

Highest level of quality control guaranteed. Precise down to 01005, detects missing, wrong or misaligned parts and solder issues.

X Ray

X-ray inspection delivers superior image quality with excellent resolution and sensitivity for laboratory and failure analysis applications.

Dual Nozzle inline Selective Soldering

All-in-one inline selective soldering machine provides increased productivity, reliability, and ultimate flexibility.

P-Primo Large Board Automatic Printer

The P-Primo Large Platform SMT Screen Printer offers board handing from 100mmx65mm minimum to 580mmx610mm maximum and board thickness of 0.4-0.8 mm.

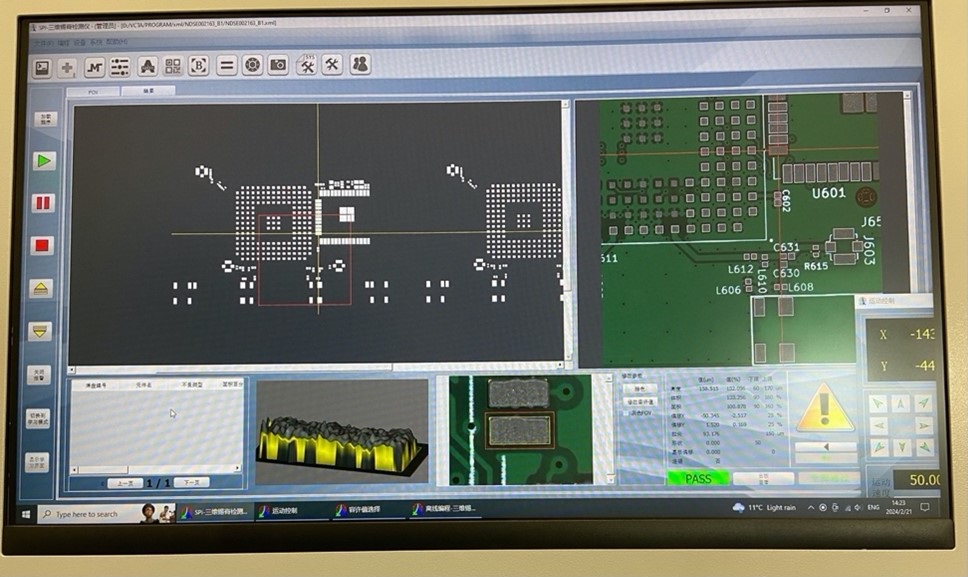

3-D Paste Inspection Machine

3-D paste inspection machine that spots out every flaw of the paste placed on the PCB. Ultimately eliminates the PCB soldering problems. More info FAQ 18.

Temperature Chamber

Temperature Chamber enables some preliminary tests for the finished boards. The temperature range can be set from -40 to 150 Celsius and the relative humidity from 20% to 98%. The chamber room space is one cubic meter.

Conformal Coating

New added Conformal Coating equipment provides industrial standard coatings for various PCB boards.

UV Laser PCB/FPC depaneling machine

UV Laser PCB/FPC depaneling machine, its overall processing precision is less than 30 micrometres (um), and the positioning precision is ±3um. This high level of precision reduces the risk of damage to the boards or components during the depaneling process. The use of this machine can greatly increase production efficiency, which is a significant advantage in the fast-paced electronics manufacturing industry. This machine is particularly beneficial for customers who produce very precise boards, especially those with components installed close to the edges where the boards are separated.

3-D AOI

A newly added 3D AOI (Automatic Optical Inspection) machine, that is equipped with a camera of 12-megapixel resolution, ultra-speed of 189 frames per second, in 360° from 4 directional projection, at the accuracy of 8μm to identify the components, the paste, especially for the IC chips, if there are issues that commonly happen such as part miss, shift, skew, overturn/reverse, paste overflow or insufficient, circuit short, and so on, before the boards going through the oven or after the boards soldered. It greatly enhanced the PCB assembly quality and lifted production efficiency.

Our process

Our assembly process uses two complete surface mount lines with the most sophisticated pick and place machines available that can handle even the tiniest (01005) of components. An automatic selective soldering system aids installation of through-hole parts on mixed-part boards effectively. Our automatic optical inspection (AOI) machine and X-Ray facilities are used to complete meticulous inspections to catch and eliminate any potential installation and soldering flaws.

At U Choice

- Over 10,000 Sq feet of operation and production spaces with anti-static flooring and grounded workstations.

- Professionally deployed facilities and equipment that sustained production efficiency and exalted overall product quality.

- Environmental-friendly workplace by equipped with emission, dust discharge control and air-conditioning systems where a normative and healthy working environment is set.

- Advanced equipment and machinery to assuring high quality products are built and maintaining the plant’s high productivity.

- Certified in ISO 9001 since 2015.

- 80% of Line Operators carry IPC-610A Certification

- CSA Certified Machinery & Equipment

- RoHS Certified

- IPC Standards for highest quality production

Certifications