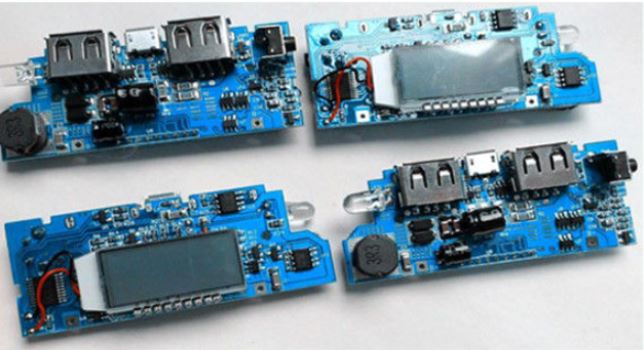

Complex Double sided assembly

To achieve higher component density, the double-sided assembly technology has evolved double-side circuits that have copper tracking and component pads (land pattern) on the top and bottom side of the PCB, and often each side is interlinked by through-hole vias. Double-sided assembly requires the placement of components on both sides of the PCB. Where a double-sided assembly is surface mount, the solder pasting, and component placement process is as described in SMT Assembly.

To populate the underside with surface mount components, the PCB is inverted, and the pasting and component placement process is simply repeated. The second pass through the reflow oven does not melt the previously soldered side, as the joints are protected from the direct heat by being on the underside of the assembly.

This method is very common, and almost all surface-mount components are specified to withstand maximum reflow temperatures with two passes through the reflow oven. Further passes through any other soldering process may compromise the components’ reliability.